Case Study: Drone Services Provider Navigates a 2,500-Acre Gold Mine Site in Fiji with ROCK LiDAR

Jan 31, 2023

This project has everything. Gold mines. Volcanoes. Dense vegetation. Treacherous terrain. Wild weather conditions. And drones beaming lasers toward the ground at 720,000 pulses per second. If you ask us, this should be the plot for yet another Indiana Jones sequel.

But it’s real life! This aerial LiDAR surveying project actually happened in a remote area of Fiji. While we do intend to give due diligence to this impressive aerial surveying project by the ROCK Stars at Kahuto Pacific, it’s impossible to do so in a dry case study. So, allow us to "geek out" for a minute while sharing the results of this epic endeavor.

Project Snapshot

- ROCK Client: Kahuto Pacific (Suva, Fiji)

- **Kahuto Pacific Client: **Canadian mining company operating in Fiji

- **Assignment: **The client needed accurate contours for the challenging 2,500-acre site, which includes a large gold-mining operation.

- **Result: **Kahuto delivered contours that helped its client determine where to construct key infrastructure features.

ROCK Client: Kahuto Pacific in Suva, Fiji

Kahuto Pacific specializes in the capture and process of spatial and visual data for the Pacific’s leading engineering, surveying and land development consultants. It utilizes cutting-edge drone and photogrammetry technologies like the ROCK R2A LiDAR to deliver the most effective and compelling solutions, including surveys, inspection and monitoring. Kahuto is emerging as the LiDAR leader in its area of the globe.

Equipment Used

The Kahuto Pacific team used a DJI M300 drone fitted with a ROCK R2A LiDAR system. The point cloud data was processed with ROCK Cloud software.

Problem

Kahuto Pacific was hired by a Canadian mining company to provide topographic, aerial LiDAR for 2,500 acres (1,000 hectares) of densely vegetated, mountainous terrain.

For context, the campus of Purdue University in West Lafayette, Indiana, is 2,500 acres and includes 160 buildings on its mostly flat property. Remove the buildings and add thousands of trees and perilous elevation drop-offs, and you can get a good sense of the area.

The site was a massive area full of challenging mountainous terrain (near a volcano, nonetheless). The terrain had dense vegetation throughout much of the area, which usually makes generating topos difficult and/or inaccurate. The client needed bare earth models to aid in determining where key infrastructure elements needed to be built.

Most of the area was impassable by vehicles, so equipment was transported via horseback. In addition, heavy rainstorms delayed capturing data and also made the terrain more hazardous to traverse.

As if the terrain wasn’t tricky enough, that wasn’t what made the project a big risk for Kahuto Pacific. The company already had a proven track record of successful photogrammetry projects, including aerial surveys of 10,000-acre (40 sq. km) sites, but had never used LiDAR to capture point cloud data. This wasn’t exactly the kind of project you dip your toe in the water for, but the Kahuto team couldn’t resist at least exploring the opportunity.

“These guys were a big company that needed a good dataset,” said Christopher Saili, Managing Director of Kahuto Pacific. “They had a lot riding on it, and I could feel it. So we went in all guns blazing and got it done.”

Solution

Saili and his team had to conduct a prudent round of risk assessment. They turned to ROCK Robotic. At the time, an industry peer / business reference was working for a surveying company that used a ROCK R2A LiDAR scanner and ROCK Cloud for many of its jobs.

“The planning — having help from someone who had used ROCK before — helped us go through the process of risk assessment,” Saili offered. “ROCK worked with us to understand what we needed to deliver, from flight height to the placement of the ground control points to post-processing of the data.”

Once Saili thoroughly discussed and vetted both the process and the ROCK hardware and software with ROCK, Kahuto Pacific decided to move forward with the gold mine site data capture. “That really helped us realize this was a risk worth taking. There were proven steps to deliver a reliable dataset,” remarked Saili.

After scouting and gridding the area, then placing GCPs on horseback, the Kahuto team conducted dozens of drone flights using the DJI M300 and captured point cloud data using the ROCK R2A, until every point of the entire 2,500-acre area was captured.

While it’s easy to read the previous sentence as a quick summary of the data-capturing process, it certainly wasn’t easy on the ground. “We were carrying generators, M300s, and big heavy equipment,” Saili recalled. “We were riding on horseback for hours through rainy, steamy, hot, muddy terrain. You’d look up at the sky in the area you’re trekking into, and it would be clear. An hour and a half later, you’d be standing on the mountain, and rain would begin to roll through. That was such a challenge and an adventure. But we were able to deliver.”

Results

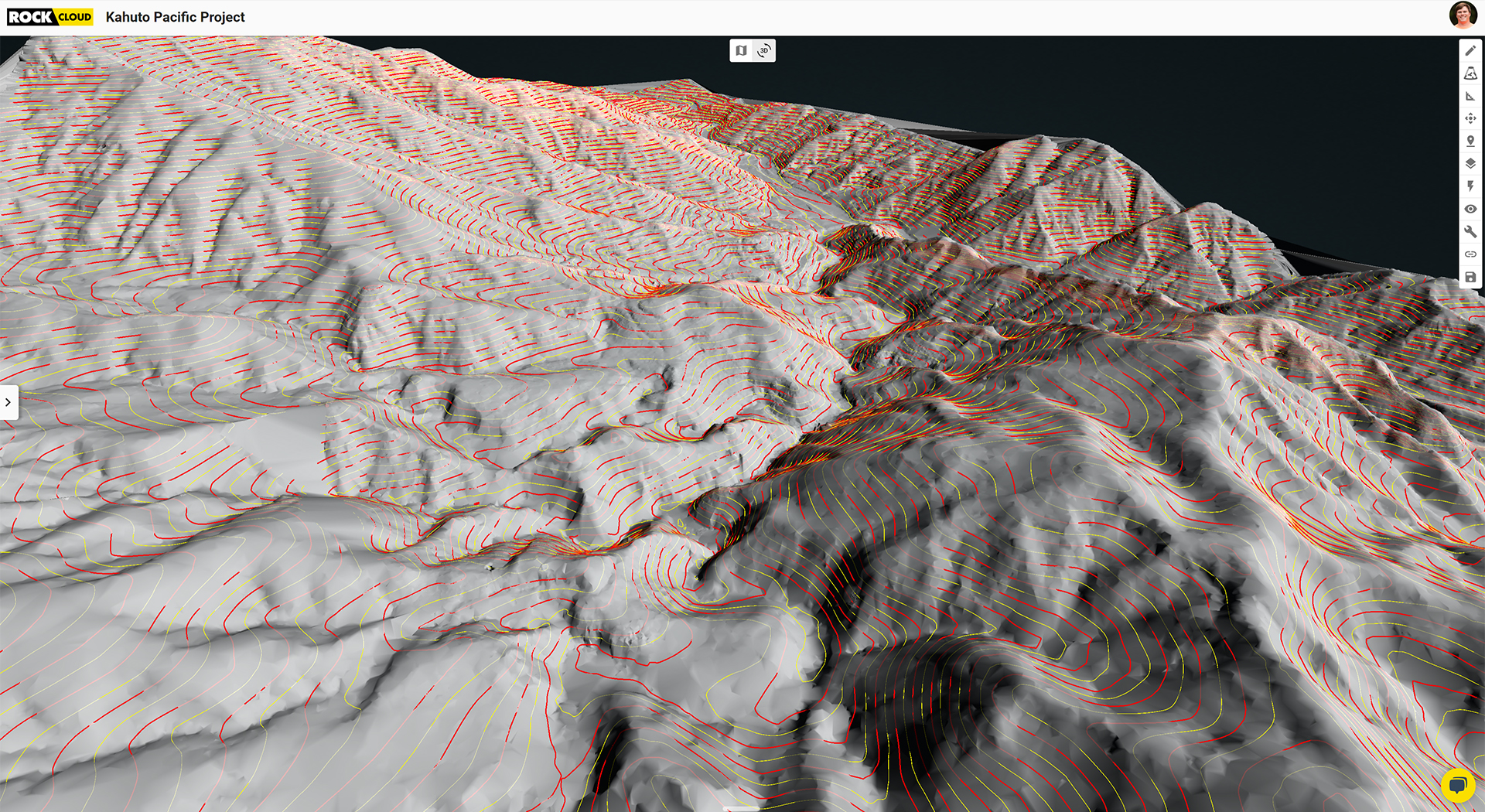

The Kahuto Pacific team processed the datasets in ROCK Cloud and ordered contours and DEMs through ROCK Surveyor. In total, they captured a mind-boggling 5.5 billion points of data. That's "billion" with a "b."

Kahuto’s client used the data to tender out the work for their tailings dam and immediately started the design work for their mill site. Once the client got their LiDAR data from Kahuto, their geologist was instantly able to look at it to determine precisely where they needed to drill. “Their eyes lit up once they saw the digital terrain model with the contours overlaid,” Saili shared.

“The thing that I’m most pleased about is the ease of use of the LiDAR. We were able to take the hardware and deliver a product for the first time at such challenging terrains and at such a decent scale. A thousand hectares for our first [aerial LiDAR] project with mountainous terrain.”

Kahuto Pacific’s first LiDAR project — a 2,500-acre undertaking — was a massive triumph. “Honestly, this was such a big thing for us," Saili commented. "The client is absolutely over the moon with the data we delivered.”

“The client is absolutely over the moon with the data we delivered.”

— Christopher Saili, Managing Director, Kahuto Pacific

The ROCK Support Team often gets questions about the ability for the R2A or R360 to capture accurate point clouds in areas with dense vegetation. The proof is in the pudding here; ROCK LiDAR breaks through tree canopies to deliver stunning, accurate views of vegetation.

Saili summed up his experience surveying the gold mine site this way: “The [ROCK] LiDAR made things easy. This project has been incredible end to end — from us using the LiDAR equipment, the client being happy with the data — it’s just been a big, big win.”

What’s Next for Kahuto Pacific?

Based on the successful delivery of contours for this project, Kahuto Pacific has gotten dozens of large-scale projects from other clients and contractors in and around Fiji. The company plans to expand its aerial LiDAR surveys and drone services to Vanuatu and Papua New Guinea, which will allow them to cover the entire Central and Eastern Pacific regions. The sky’s the limit.

**Visit rockrobotic.com **to learn more about our survey-grade LiDAR hardware and processing software.