Case Study: Construction Company Saves $300k by Updating Contours with ROCK Cloud

Jan 10, 2023

How can a construction company save $300,000 in materials and man-hours alone over the course of seven projects? By using ROCK Cloud to compare contours. For Leonard S. Fiore Inc., it was as simple as that.

PROJECT SNAPSHOT

- **ROCK Client: **Leonard S. Fiore Inc. (LSF)

- LSF Client: Claysburg-Kimmel High School in Claysburg, Pennsylvania

- **Assignment: **Claysburg-Kimmel High School contracted LSF to remodel its entire sports field complex. Using LiDAR, LSF measured accurate contours prior to pouring concrete for new football stadium bleacher footers.

- **Result: **Prior to pouring concrete footings for football bleachers, accurate LiDAR contours saved the company $8,200 in materials and man hours alone for this portion of the project.

Here's the top-level takeaway: Companies and contractors can save a significant amount of money in Construction and Earthworks projects by comparing existing contours with updated LiDAR data.

LSF used its ROCK R2A LiDAR to capture point cloud data and ordered contours through ROCK Surveyor.

Existing contours on project sites are often old and outdated, and many surveying and construction companies don’t bother to re-survey the ground.

For this case study, we talked to Nino Efendic, Construction Technologies Integrator for LSF, about a recent LSF project. Although the $8,200 is a small portion of the $300,000 LSF saved using LiDAR for seven projects, it illustrates the point that Construction and Earthworks companies need to be using LiDAR to create accurate contours. The more lucrative savings projects haven’t been discussed here because they are ongoing and/or private.

ROCK CLIENT: Leonard S. Fiore Inc. in Altoona, Pennsylvania

Leonard S. Fiore Inc. (LSF) is a third-generation, family-owned commercial construction builder with offices in Altoona and State College, Pennsylvania. LSF has been completing projects since 1954 and has completed more than $1 billion in construction projects across eight Mid-Atlantic states. LSF employs more than 150 skilled trades professionals to self-perform work across 15 specialties, including earthwork, utilities, foundations, and cast-in-place concrete.

EQUIPMENT USED

Nino used a DJI M300 RTK drone with ROCK R2A LiDAR. His team used the Emlid Reach RS2 for additional data collection and a Topcon Hiper VR base and rover to capture GCPs. Efendic processed the point cloud data in ROCK Cloud.

PROJECT BACKGROUND

LSF was contracted to complete athletic field improvements to a local high school. Improvements included new baseball and football fields, upgraded light towers and bleachers. The proposed bleachers were on the slope adjacent to the main football field.

The footers of the bleachers were required to be set three feet below the existing grade. While beginning the excavation of the footers, LSF discovered discrepancies in the elevations shown on the plans. If crews were to follow the top-of-footer elevations listed on the plans, nearly half of the footers would be sitting on grade rather than three feet below.

SOLUTION

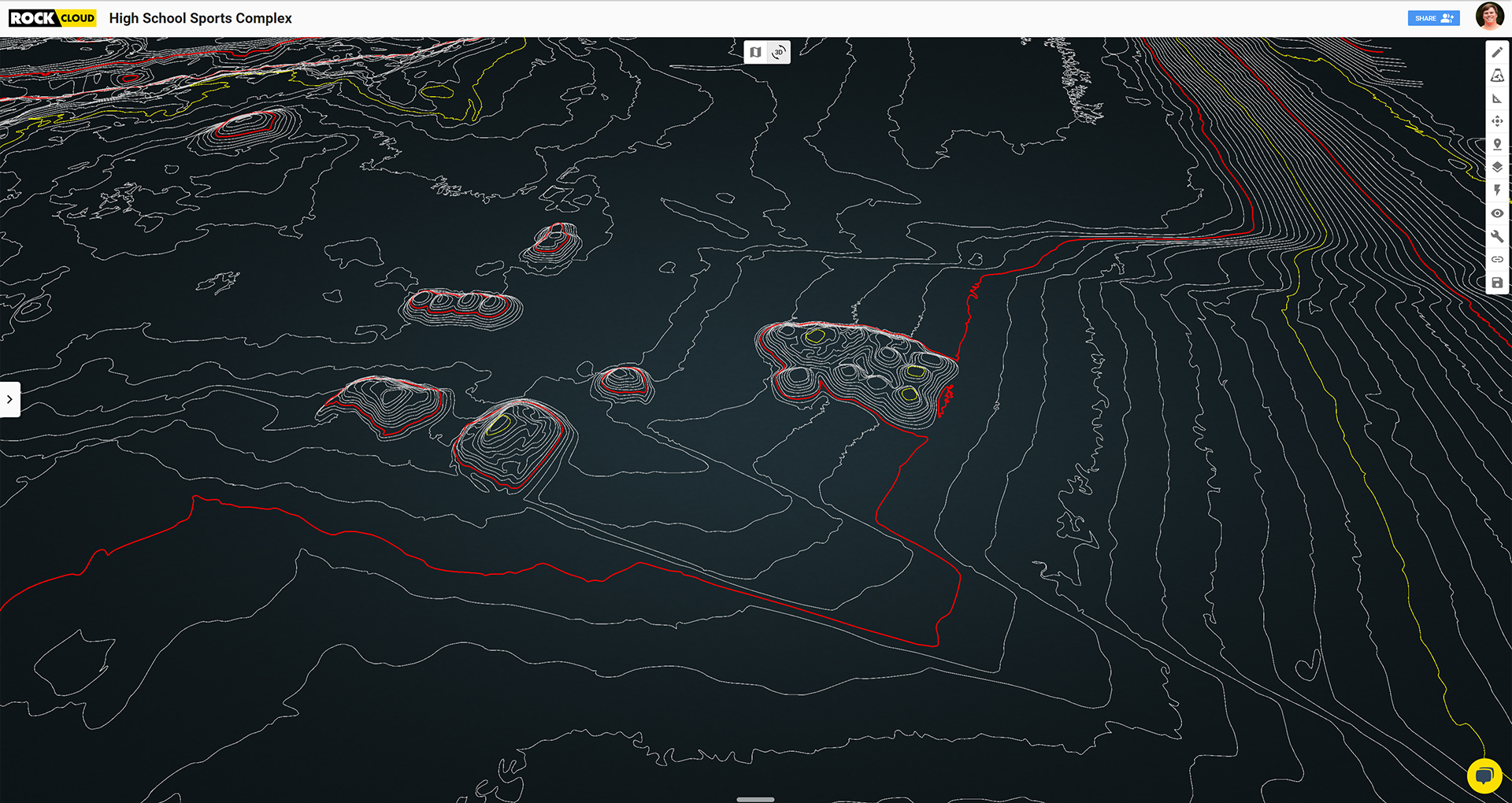

Efendic captured contour data with the ROCK R2A and used ROCK Surveyor to get a ground-only classification. From there, they overlaid the CAD files for the footers to find the elevations on each row. This meant the LSF team would have a net zero cut fill, meaning they didn’t need to remove any dirt from the site.

Using the LiDAR data originally collected for the Earthworks operation, Efendic was able to reestablish the proper top-of-footer elevations per the true contours of the slope in question. After further analysis, it was found that across the footprint of the bleachers, the contours listed on the approved prints were one-to-two feet higher than the true elevations found onsite.

RESULTS

By getting accurate contour measurements, the LSF team saved an estimated $8,200 just in concrete costs and man hours. This doesn’t even account for fuel costs for the equipment to remove potential concrete already poured.

LSF continues to incorporate LiDAR into the early phases of its construction projects. According to Efendic, “What we've been doing with ROCK LiDAR is comparing existing contours that were given as prints to actual true LiDAR contours. We find that, more often than not, the existing contours found on the prints are incorrect. And because of that, we've been able to identify either savings or profits for our company.”

When working with a client on Earthworks or Construction projects, LiDAR helps to accurately measure contours and quantify the exact amount of dirt to move or concrete to pour. LSF’s example with the bleacher footers has only been the tip of the iceberg for them, as they have used LiDAR with similar projects seven times over the past four months alone.

“The fact that we're showing this big of an improvement is a testament to the other guys who aren't doing much [LiDAR capturing]. They should probably get on board.” *–Nino Efendic, Construction Technologies Integrator *

Efendic continues to calculate growing savings for LSF, as the accurate contour measurements have more than paid for the equipment and software. He summarized by saying, “Just looking at the gains and the ROI that we're getting should be very, very alarming to the people that do a lot of Earthwork projects.”

Efendic recommends to Construction and Earthworks surveyors: “The fact that we're showing this big of an improvement is a testament to the other guys who aren't doing much [LiDAR capturing]. They should probably get on board."

Visit rockrobotic.com to learn more about our survey-grade hardware and processing software.